212-204-0075

info@pyvot.tech

Degassing Fluids Are Important To Performance – Significance of Degassing Fluids

Degassers prevent imprecise sampling, uphold flow rate, and decrease inaccuracies by eliminating dissolved gases, even in intricate fluid systems, prior to their outgassing into bubbles. Integrating degassing into your fluidic circuit is crucial for obtaining dependable and precise outcomes.

Advantages of Degassing

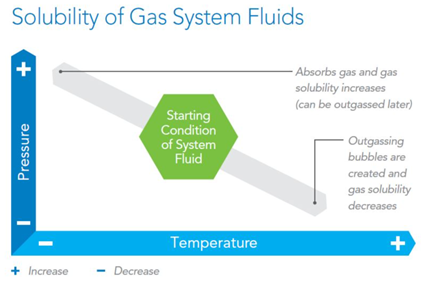

By degassing fluids well below their saturation point, precision is significantly enhanced, and instruments can operate without interference from bubbles. This eliminates the need for repeated sampling, thereby increasing throughput in your fluidic pathway. Variations in temperature, pressure, reagent concentration, and agitation can all lower the saturation point of system fluids, leading to the formation of bubbles due to outgassing. Failure to identify bubble formation at the outset can compromise the accuracy of sample analysis.

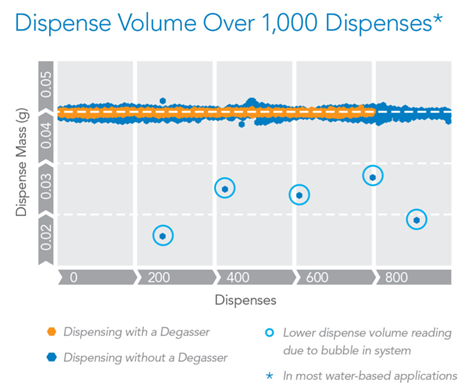

Incorporating a degasser into your instrument can help you achieve consistent and accurate sample results. Degassers effectively enhance precision by removing gas from fluids, even below the saturation point, thus ensuring bubble-free instrument operations. The accompanying graph illustrates how the use of degassers significantly enhances accuracy over time for dispense volumes during standard operation.

Our degassers utilize closed-loop vacuum control to effectively maintain efficiency over a broad range of flow rates and conditions. This feature significantly enhances the reliability of consecutive runs and the overall throughput while preserving the dispense accuracy to prevent sample loss.