212-204-0075

info@pyvot.tech

End-Capping Technology for Sunniest and SunShell

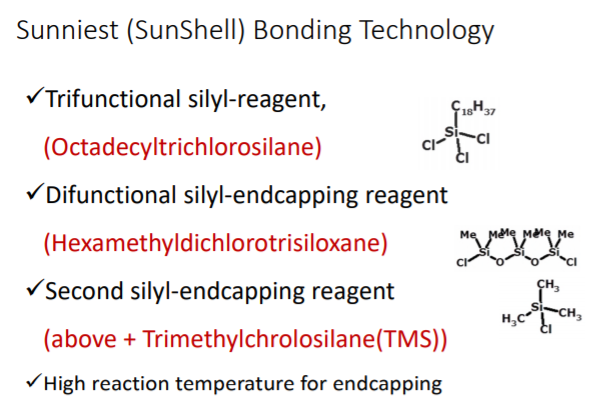

| Sunniest (SunShell) Bonding Technology | ||||

| This is the essence of the Chromanik Sunniest and SunShell bonding technology: A.)The main tri-functional silyl reagent. B.) Two end-capping reagents: 1. Difunctional silyl end-capping reagent 2. Second end-capping reagent, monofunctional reagent are used. There is a reaction that occurs at greater than 200°C. |  | |||

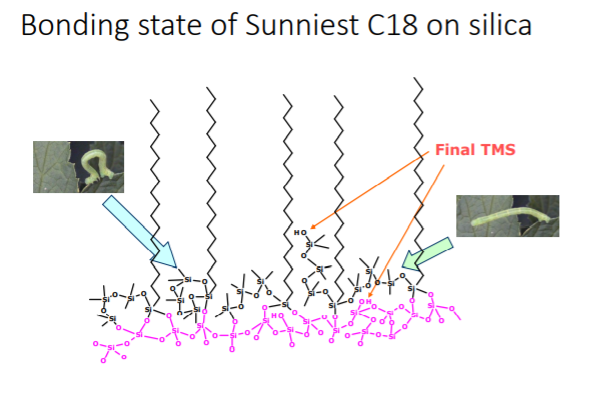

| Bonding State of Sunniest C18 on Silica | ||||

| A unique trifunctional silyl reagent was developed as shown in Figure 1. This silyl reagent can bond with any silanol group on the silica surface as shown in Figure 2 because it can expand and contract on its own. This technique reduces the residual silanol groups to almost none on the C18 stationary phase. Finally, end-capping was done with trimethylsilyl-reagent (TMS). This makes the Chromanik Sunniest and SunShell columns provide advantages that include: 1) The least amount of peak tailing for basic compounds 2) Height-stability |  | |||

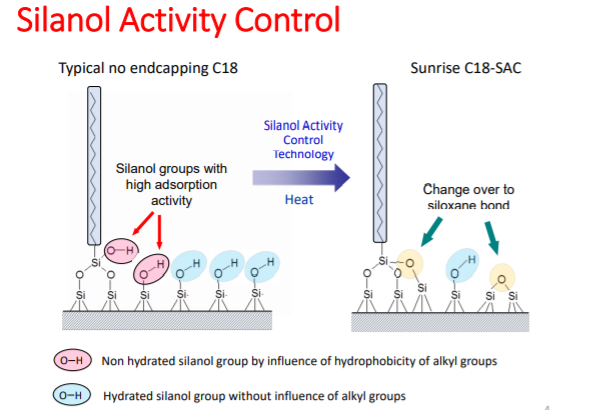

| Silanol Activity Control | ||||

| The Silanol Activity Control is a unique technology developed by Chromanik. A typical no end-capping column has both non-hydrated silanol groups and hydrated silanol groups. The hydrated silanol groups act as ion exchange and do not have an absorption point. The non-hydrated silanol groups absorb basic compounds. Through Chromanik’s Silanol Activity Control Technology, there is a reaction of greater than 200°C in which the silica gel becomes amorphous. This causes the silanol groups to combine to form a siloxane bond. The Sunrise C18-SAC column does not absorb basic compounds and there is no peak-tailing despite not having end-capping. |  | |||

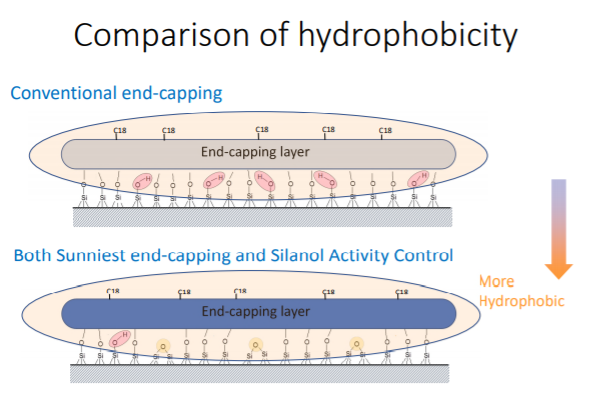

| Comparison of Hydrophobicity | ||||

| The Chromanik Silanol Activity Control provides advantages in relation to hydrophobicity. A conventional C18 column has residual non-hydrated silanol groups that contribute as a polar site which makes hydrophobicity of the stationary phase decrease. The high temperature reaction of greater than 200°C causes the Silanol Groups to combine to form a siloxane bond. The siloxane bonds do not cause hydrophobicity to decrease. This gives Chromanik Sunniest and Sunshell columns a strong advantage. |  | |||

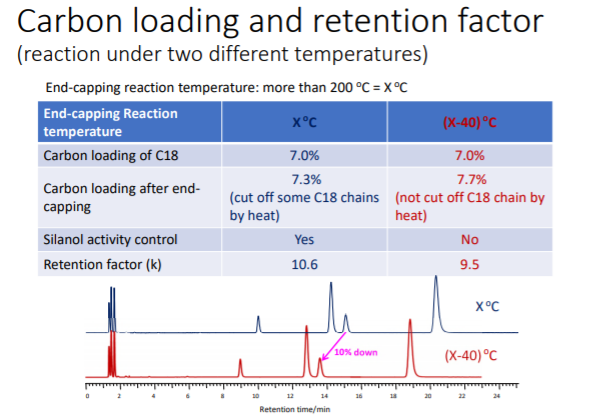

| Carbon Loading and Retention Factor | ||||

| Chromanik technology involves a reaction of more than 200°C. The illustration shows a comparison between conventional end-capping of at least 40°C less than Chromanik's end-capping technology that is over 200°C. The standard Carbon loading of a C18 is 7.0°C. In the case of carbon loading after end-capping Chromanik has a smaller carbon loading percentage as some C18 chains were cut off by heat. However, Chromanik columns have a higher retention factor (k) due to its Silanol Activity Control. Chromanik columns have a higher retention factor but have a slightly higher retention time than competitive technologies. |  | |||

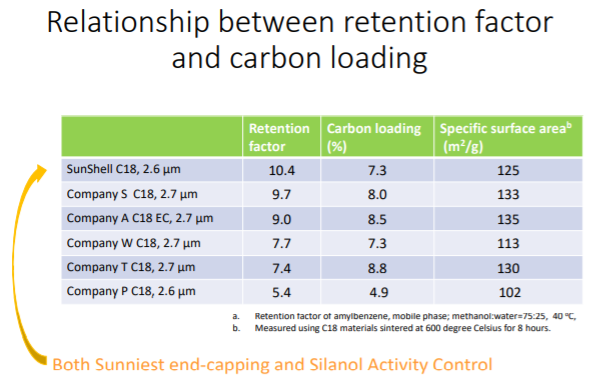

| Relationship Between Retention Factor and Carbon Loading | ||||

| Despite not having the highest Carbon Loading (%) the Chromanik SunShell 2.6um column had the highest Retention Factor. The SunShell C18 was the most retentive as a result of the Silanol Activity Control Technology. |  | |||

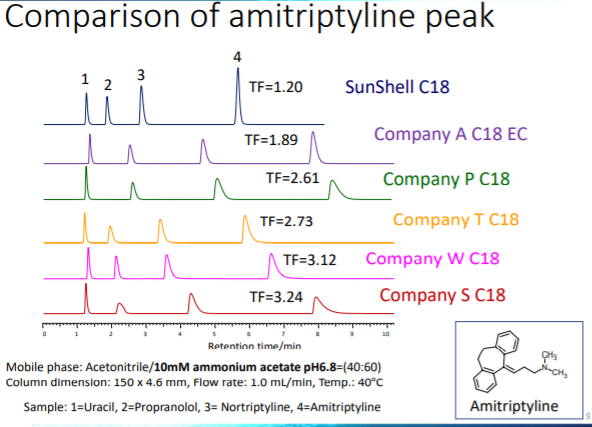

| Comparison of Amitriptyline Peak | ||||

| This slide shows a comparison of amitriptyline peak using acetonitrile and 10mm ammonium acetate mobile phase. SunShell C18 showed a good peak shape. The SunShell column also showed the least amount of Tailing Factor (TF) as highlighted above. |  | |||

| Stability Under Acidic pH Condition | ||||

| This slide shows stability under an acidic pH condition. The upper information notes the durable test condition. Mobile phase is acetonitrile and 1.0% TFA pH1 (10 to 90) and the temperature is 80°C. This condition is accelerated. As a comparison at 90% of relative retention, SunShell C18 shows solid stability up to 120 hours, which is significantly better than the competitive columns displayed. |  | |||

| Stability Under Basic pH Condition | ||||

| This slide shows stability under a basic pH condition. The upper information is the Durable condition. Mobile phase is methanol and 20 mM sodium borate and 10mM sodium hydroxide (30 to 21 to 49) pH 10. Temperature is 50°C. Under a basic pH condition, C18 is deteriorated by dissolving silica gel and avoid yields in the column so that the theoretical plate decreases. The vertical axis Relative plate of butylbenzene /%. SunShell C18 can be used 5000 mL of elution volume which shows our column to be much more stable than the other players. |  | |||

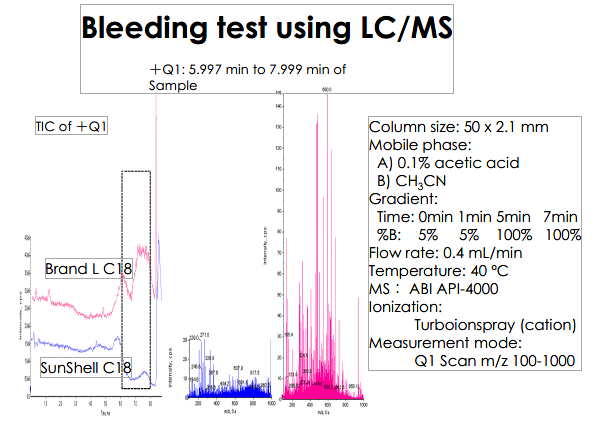

| Bleeding Test Using LCMS | ||||

| This is a bleeding test under 0.1% acetic acid and acetonitrile, gradient elution condition using LC/MS. The information highlighted in Red is a competitive brand. The information highlighted in blue is SunShell C18. The left figure shows a baseline of total ion chromatograms. The right figure shows total mass spectra from 6 min to 8min. Bleeding from SunShell C18 column is very low compared with the conventional C18 column. |  | |||

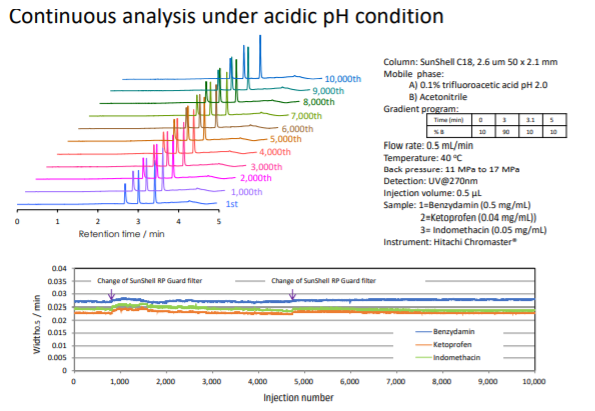

| Continuous Analysis Under Acidic pH Condition | ||||

| This slide shows a continuous analysis under acidic pH condition. Using SunShell C18 2.6 um 50 mm length and 2.1 mm inner diameter. A mobile phase is 0.1% trifluoroacetic acid pH 2.0 and acetonitrile. Using gradient elution; a flow rate of 0.5 mL/min and temperature is 40 oC . Sample include: benzydamin, ketoptofen and Indomerthacin. The same chromatograms were consistent for over 10,000 injections. The peak width of each component shown in the lower figure remains relatively unchanged |  | |||

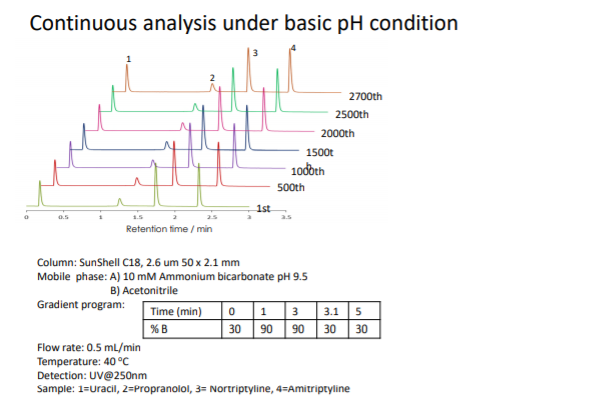

| Continuous Analysis Under Basic pH Condition | ||||

| This slide shows continuous analysis under a basic pH condition. The mobile phase includes 10 mM Ammonium bicarbonate, pH 9.5, and acetonitrile. Gradient elution is applied. The Chromanik SunShell C18 column was stable extending beyond 2,500 injections of the sample. |  | |||