212-204-0075

info@pyvot.tech

SunArmor C18

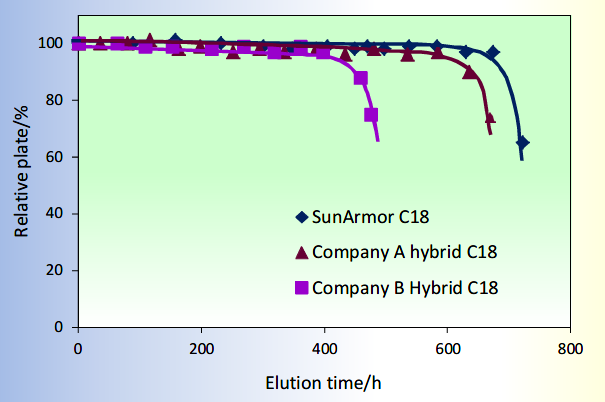

Stability Under Basic pH Condition

Almost the same stability compare with the hybrid C18s.

Durable test condition

Column size: 50 x 2.1 mm

Mobile phase: CH3OH/10mm Ammonium

bicarbonate (pH10.5)=30/70

Flow rate: 0.8 mL/min

Temperature: 60ºC

Measurement condition

Column size: 50 x 2.1 mm

Mobile phase: CH3CN/H2O=60/40

Flow rate: 0.2 mL/min

Temperature: 40ºC

Sample: 1 = Butylbenzene

As a result of the special end capping, SunArmor has strong alkali resistance. It has the same or higher durability than competitive companies with hybrid C18 Columns.

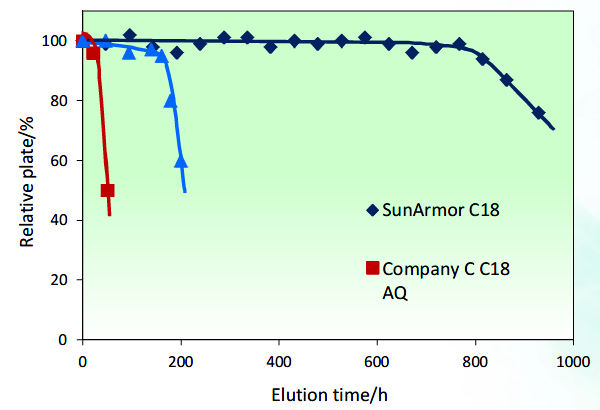

Stability Under Neutral pH Condition at 80ºC

Durable test condition

Column size: 50 x 2.1 mm

Mobile phase: CH3OH/10mm

Ammonium acetate (pH6.8)=30/70

Flow rate: 0.2 mL/min

Temperature: 80ºC

Measurement condition

Column size: 50 x 2.1 mm

Mobile phase: CH3CN/H2O=60/40

Flow rate: 0.2 mL/min

Temperature: 40ºC

Sample: 1 = Butylbenzene

By raising the column temperature, it is possible to shorten the analysis time in a mobile phase with high viscosity and improve the separation in the case of substances with slow diffusion such as polymers. The high durability of Sun Armor is very effective even in high temperature analytical conditions.

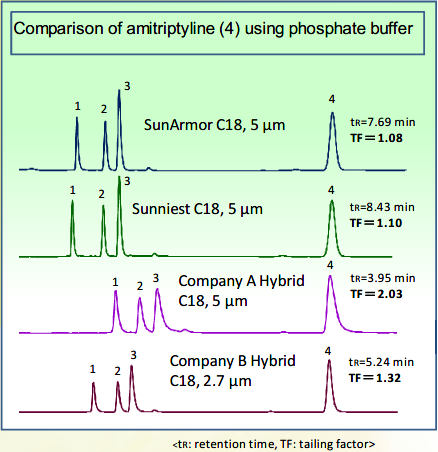

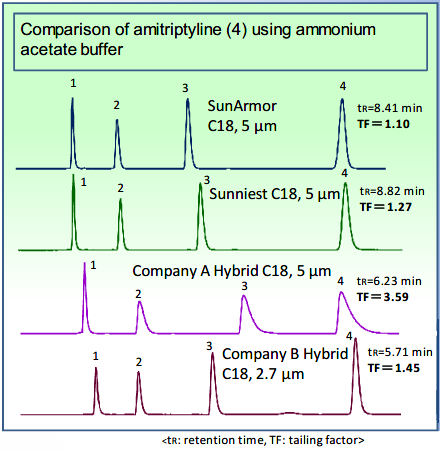

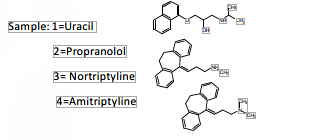

Peak Shape of Basic Compound

Condition (amitriptyline)

Column dimension: 150 x 4.6 mm

Mobile phase:

A) Acetonitrile/20mm phosphate buffer pH7.0=(60:40)

B) Acetonitrile/10mm ammonium acetate pH6.8=(40:60)

Flow rate: 1.0 mL/min Temperature:40ºC

The evaluation was performed with amitriptyline, which is often used to evaluate residual silanol groups. In addition, this compound has a more pronounced effect of residual silanol groups when the mobile phase is acetonitrile.

Like the Sunniest series, SunArmor C18 eliminates the effects of residual silanol groups. It maintains a sharp peak shape even in compounds and conditions that are easy to peak tail.

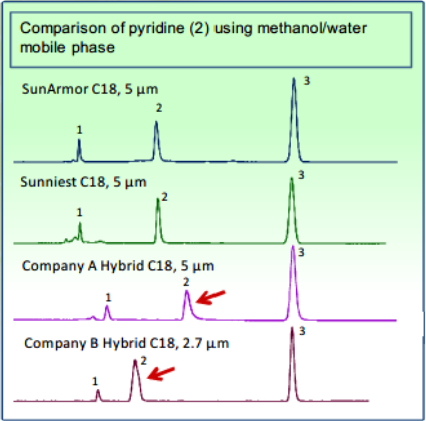

Condition (pyridine)

Column dimension: 150 x 4.6 mm

Mobile phase: CH3OH/H2O=30/70

Flow rate: 1.0 mL/min

Temperature: 40ºC

Detection: UV@250nm

Sample: 1 = Uracil, 2 = Pyridine, 3 = Phenol

Pyridine is a compound that is prone to tailing due to residual silanol groups. Also, if even a small amount of acid remains in the stationary phase, the peak will be abnormal. The synthetic technology that enables Sun Armor’s high durability minimizes residual silanol and performs appropriate cleaning accordingly. Additionally, SunArmor provides for a excellent peak shape.

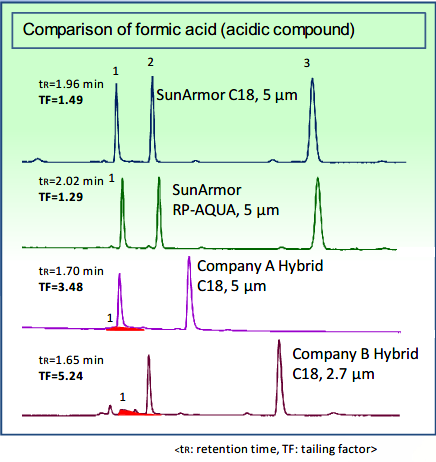

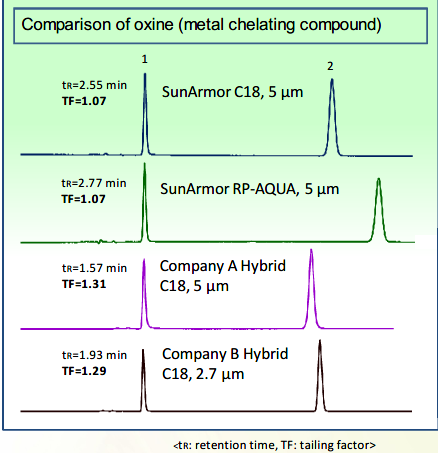

Peak Shape of Acidic and Metal Chelating Compounds

*Hybrid C18s showed a very poor peak shape for formic acid. It is doubted that some amines as a by-

the product remained on the surface of the packing

materials.

Condition (formic acid)

Column dimension: 150 x 4.6 mm

Mobile phase: CH3CN/0.1% H3PO4=2/98

Flow rate: 1.0 mL/min

Temperature: 40ºC

Detection: UV@210nm

Sample: 1 = Formic acid

2 = Acetic acid

3 = Propionic Acid

Condition (oxine)

Column dimension: 150 x 4.6 mm

Mobile phase: CH3CN/20mm H3PO4=10/90

Flow rate: 1.0 mL/min

Temperature: 40ºC

Detection: UV@250nm

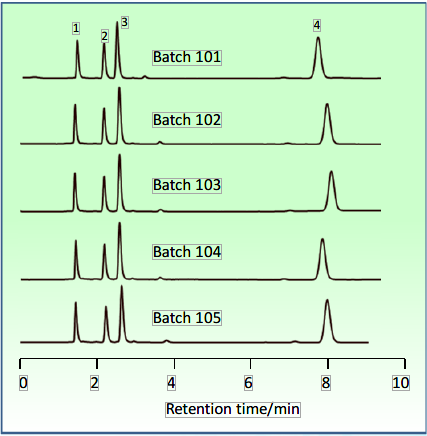

Reproducibility in retention of SunArmor C18

Condition (amitriptyline)

Column dimension: 150 x 4.6 mm

Mobile phase: Acetonitrile/20mm phosphate buffer

pH7.0=(60:40)

Flow rate: 1.0 mL/min

Temperature: 40ºC

| Batch | Retention Time |

| 101 | 7.69 min. |

| 102 | 7.97 min. |

| 103 | 8.12 min. |

| 104 | 7.85 min. |

| 105 | 7.93 min. |

| Average (Av) | 7.91 min. |

| Standard deviation (σ) | 0.14 min. |

When a silylation reagent having a dimethylamino group as a functional group is used, an amine as a by-product remains in the packing material. This amine strongly adsorbs formic acid and causes tailing. If formic acid is tailing, as in companies A and B, it is possible that amines may remain in the packing material.

SunArmor C18 uses a newly developed silylating agent and excellent synthetic technology to eliminate various challenges.

8-Kinolinol (oxine) is a metal-coordinating compound that exhibits tailing in the presence of metal impurities in the packing material.

However, SunArmor C18 is manufactured by using silica particles with few impurities and eliminating contamination during synthesis, so there is no need to worry about the effects of metal impurities.