Shop

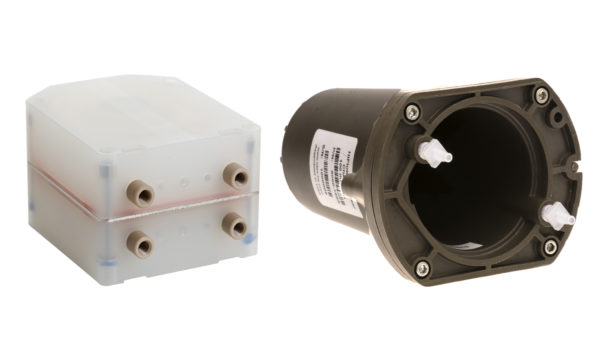

PREPARATIVE DEGASSING CHAMBERS

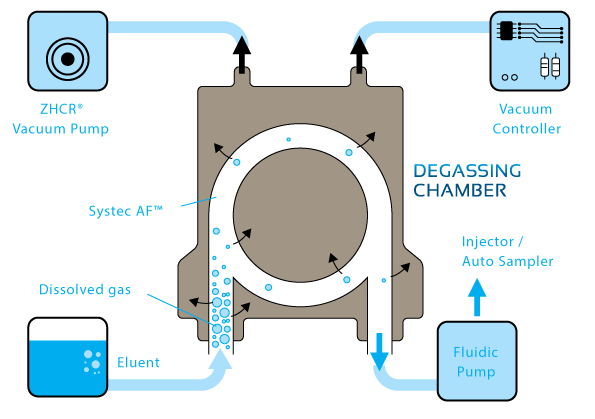

The standard preparative degassing chamber was designed to be easy to prime and is configured with a Teflon® AF degassing membrane (tubing) to provide maximum degassing capacity with the absolute minimum internal volume (less than 3% of PTFE designs with comparable degassing capacity) and a chemically inert, metal-free flow path. Degassed mobile phase is available in less than a minute!

Description

PREPARATIVE DEGASSING CHAMBERS

General Specifications

- Degassing Channel Tubing: Systec Teflon AFTM, 0.075 in. ID

- Degassing Channel Pressure Rating: 70 PSIG (testing pressure)

- Wetted Materials: Systec AF, PPS, stainless steel and Glass-filled PTFE

- Housing Materials: Polypropylene and stainless steel

A. Custom configurations are available. Consult us for your own OEM solution to your specific application.

B. The standard prep scale chambers are not recommended for GPC applications or for use with HFIP (hexafluoroisopropanol).

C. The flow rates given are for a gradient mixture of 60/40 MeOH/H2O, with a typical low-pressure gradient mixing valve.

Higher flow rates are possible with high-pressure mixing.

D. Estimated tubing pressure per unit change in flow assuming laminar flow with a viscosity of 1,0 cP

Additional Information

| Model | 1 Ch 15mL/min, 2 Ch 15mL/min Stented/GPC compatible, 2 Ch 20mL/min, 2 Ch 40mL/min, 100 ml/min, Systec AF |

|---|