212-204-0075

info@pyvot.tech

Strongly Acidic Cation Exchange Resins

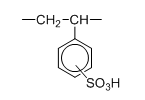

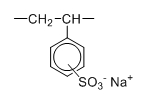

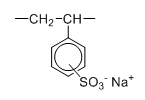

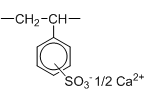

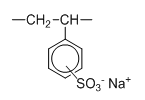

Resins with sulfonic acids as their functional groups, are called strongly acidic cation exchange resins, since their acidity is strong as hydrochloric acid or sulfuric acid. DIAIONtm SK, PK, and HPK series belong to this classification.

SK1B resin is our “flagship” premium grade, gel-type, strong acid cation resin. It has excellent properties for industrial applications and is recommended for industrial scale softening and demineralization applications. It has standard crosslinkage. In situations where the raw water contains oxidizing substances, the higher crosslinkage resins such as SK110 and SK112 are recommended to provide better performance and longer operating life. SK110 is also recommended for regenerable mixed bed applications.

SK104H has low (4%) crosslinkage. It is mainly used as a catalyst and special applications where low crosslinked density is necessary to allow penetration of large organic molecules,or where a faster reaction rate is required.

| Grade Name | DIAIONTM SK104H | DIAIONTM SK1B | DIAIONTM SK110 | DIAIONTM SK112 |

|---|---|---|---|---|

| Chemical Structure |  |  | ||

| Ionic Form As Shipped | H-form | Na-form | ||

| Whole Bead Count | 90 min. | |||

| Shipping Density (g/L: approx.) | 750 | 830 | 845 | 855 |

| Salt Spliting Capacity (meq/mL-R) | 1.1 min. | 2.0 min. | 2.0 min. | 2.1 min. |

| Water Content (%) | 62 – 72 | 43 – 50 | 35 – 45 | 32 – 42 |

| Particle Size Distribution on 1180 μm (%) through 300 μm (%) | 5 max. 1 max. | |||

| Effective Size (mm) | 0.40 min. | |||

| Uniformity Coefficient | 1.6 max. | |||

| Ionic Form Conversion H Form | 95 min | - | ||

| Operating Temperature (℃) | 120 (H-form, Na-form) max. | |||

| Crosslinkage (%) | Ca. 4 | Ca. 8 | Ca. 10 | Ca. 12 |

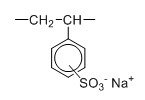

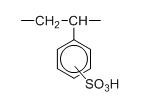

The PK resin grades are based on a porous styrene DVB polymer matrix. Their porous structure provides excellent durability against osmotic shock by swelling and shrinkage. PK216 is recommended for general water treament. PK228 is recommended for condensate demineralization (L grade is recommended for best pressure flow performance). PK grades are also recommended for special applications such as deashing, decolorization, and as a catalyst (as they have higher reaction rate in organic solvents than gel-type resins).

RCP160M has higher porous properties than PK series, and has a measurable surface area. It is generally used for special process applications such as non-aqueuos catalic reaction or cation removal from non-porlar solvent.

| Grade Name | DIAIONTM PK208 | DIAIONTM PK212L | DIAIONTM PK216 | DIAIONTM PK220 | DIAIONTM PK228 | DIAIONTM RCP160M |

|---|---|---|---|---|---|---|

| Chemical Structure |  |  | ||||

| Ionic Form As Shipped | Na-form | H-form | ||||

| Whole Bead Count | 95 min. | |||||

| Shipping Density (g/L: approx.) | 765 | 780 | 785 | 795 | 810 | 745 |

| Salt Spliting Capacity (meq/mL-R) | 1.2 min. | 1.5 min. | 1.75 min. | 1.9 min. | 2.05 min. | 1.5 min. |

| Water Content (%) | 58 – 68 | 52 – 58 | 46 – 52 | 41 – 47 | 37 – 43 | 45 – 55 |

| Particle Size Distribution on 1180 μm (%) through 425 μm (%) through 300 μm (%) | 5 max. - 1 max. | 5 max. 1 max. - | 5 max. - 1 max. | on 710 μm 25% max | ||

| Effective Size (mm) | 0.40 min. | 0.45 min | 0.40 min. | - | ||

| Uniformity Coefficient | 1.6 max. | - | ||||

| Ionic Form Conversion H Form | - | 97 min. | ||||

| Operating Temperature (℃) | 120 (H-form, Na-form) max. | |||||

| Crosslinkage (%) | Ca. 4 | Ca. 6 | Ca. 8 | Ca. 10 | Ca. 14 | - |

Chromatographical separation is widely industrialized in pharmaceuticals, fermentation and food fields. Ion exchange resins of small particles with uniform particle size distribution are applied for these purposes. The smaller particles with the more uniform particle size distribution, the higher yields and purities can be obtained. DIAION™ UBK500 series are typical cation exchange resins of this type.

| Grade Name | DIAIONTM UBK530 | DIAIONTM UBK550 | DIAIONTM UBK535 | DIAIONTM UBK555 |

|---|---|---|---|---|

| Chemical Structure |  |  | ||

| Ionic Form As Shipped | Na-form | Ca-form | ||

| Whole Bead Count | 95 min. | |||

| Shipping Density (g/L: approx.) | 825 | 850 | 840 | 865 |

| Salt Spliting Capacity (meq/mL-R) | 1.6 min. | 1.8 min. | 1.6 min. | 2.0 min. |

| Water Content (%) | 52 – 55.5 | 46 – 49.5 | 47 – 51 | 42 – 46 |

| Particle Size | 200-240μm 85% min. | 190-240μm | ||

| 90% min. | 85% min. | |||

| Ionic Form Conversion Ca Form | - | 98 min | ||

| Operating Temperature (℃) | 120 max. | |||

Ion exchange resins with good uniformity in particle size ncrease their necessity to reduce the reagents costs and spent waste waters in manufacturing pure waters. They are also used in other fields because they have little amount of large particles easy to be broken by swelling and shrinkage. Gel type ion exchange resins of uniform particle size are now launnched to meet such necessity.

UBK16 has high (16%) crosslinkage. It is used for special process application such as purification of pharmaceuticals.

| Grade Name | DIAIONTM UBK08 | DIAIONTM UBK10 | DIAIONTM UBK12 | DIAIONTM UBK16 |

|---|---|---|---|---|

| Chemical Structure |  | |||

| Ionic Form As Shipped | Na-form | |||

| Whole Bead Count | 90 min. | |||

| Shipping Density (g/L: approx.) | 840 | 850 | 855 | 865 |

| Salt Spliting Capacity (meq/mL-R) | 2.0 min. | 2.2 min. | 2.3 min. | 2.3 min. |

| Water Content (%) | 43 – 49 | 38 – 44 | 33 – 39 | 27 – 37 |

| Average Diameter (μm) | 600 ± 50 | 650 ± 50 | 600 ± 50 | |

| Uniformity Coefficient | 1.1 max. | 1.2 max. | ||

| Operating Temperature (℃) | 120 (H-form, Na-form) max. | |||

| Crosslinkage (%) | Ca. 8 | Ca. 10 | Ca. 12 | Ca. 16 |