212-204-0075

info@pyvot.tech

Strongly Basic Anion Exchange Resins

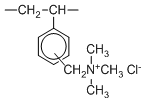

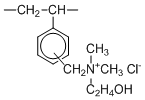

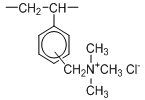

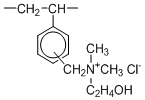

Fig3 and Fig4 show the resins with quaternary ammonium groups as their functional group. Such resins dissociate and show as strong basicity as inorganic bases like NaOH or KOH. Accordingly, they are called strong basic anion exchange resins. DIAION SA, PA, and HPA series belong to this classification.

DIAION™ strong base anion exchange resins are based on crosslinked polystyrene matrix having quaternary ammonium groups (NR3+). Among DIAION™ product line, there are SA-grades of gel-type. PA-grades of porous-type, and HPA-grades of highly porous-type. The standard shipping form is Cl– form. (in some cases OH– form is available).

Type I resins have trimethyl ammonium groups which impart higher basicity. In the co-current regeneration mode, the treated water will have the lowest silica leakage. Type I resins also have higher chemical stability and can be applied at higher temperatures (than Type II or acrylic-based resins.)

Type II resins have dimethylethanolamine groups which impart slightly lower basicity. This provides an advantage of easier regeneration (than Type I) and slightly higher capacity.

SA10A is a Type I resin with standard cross-linkage. SA12A is also a Type I resin with slightly lower cross-linkage. These resins are popularly used for water treatment. SA12A is typically recommended for the treatment of surface waters with troublesome organic content.

SA11A is Type I resin with low cross-linkage and is mainly used for special applications such as sometimes used as a mixed bed or primary bed polisher anion.

SA20A is a Type II resin of standard cross-linkage. It is popularly used for water treatment with its easy.

| Grade Name | DIAIONTM SA10A | DIAIONTM SA11A | DIAIONTM SA12A | DIAIONTM SA20A |

|---|---|---|---|---|

| Type | Type I | Type Ⅱ | ||

| Chemical Structure |  |  | ||

| Ionic Form As Shipped | Cl-form | |||

| Whole Bead Count | 90 min. | |||

| Shipping Density (g/L: approx.) | 670 | 685 | 670 | 715 |

| Salt Splitting Capacity (meq/mL-R) | 1.3 min | 0.85 min | 1.3 min | 1.3 min |

| Water Content (%) | 43 – 47 | 55 – 65 | 48 – 55 | 45 – 52 |

| Particle Size Distribution on 1180 μm (%) through 300 μm (%) | 5 max. 1 max. | |||

| Effective Size (mm) | 0.40 min. | |||

| Uniformity Coefficient | 1.6 max. | |||

| Operating Temperature (℃) | 60 (OH-form) max. 80 (Cl-form) max. | 40 (OH-form) max. 60 (Cl-form) max. | ||

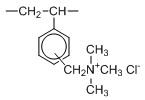

Porous-type ion-exchange resins of porous polymer matrix have good resistance against swelling and shrinking, though their exchange capacity is lower than gel-type ion exchange resins of the same degree of cross-linkage.

These are effective when highly purified effluents are needed, e.g. removal of silica to very low concentration.

They are suitable for treatments of wastewaters with organic compounds. PA312 and PA316 are generally used in wastewater treatments, and PA308 is used for demineralization and decolorization of sugar liquors.

Highly porous type resin, HPA25L, has higher cross-linkage and higher porous properties than standard PA grade resins. This is typically used for the treatment of large molecules in special process applications. They are mainly applied in enzyme purification as enzyme carriers for the treatment of bio-pharmaceutical substances, and treatment of feed solutions of high color value.

| Grade Name | DIAIONTM PA308 | DIAIONTM PA312 | DIAIONTM PA316 | DIAIONTM HPA25L |

|---|---|---|---|---|

| Type | Type I | |||

| Chemical Structure |  | |||

| Ionic Form As Shipped | Cl-form | |||

| Whole Bead Count | 95 min. | |||

| Shipping Density (g/L: approx.) | 710 | 675 | 670 | 675 |

| Salt-splitting Capacity (meq/mL-R) | 1.0 min | 1.2 min | 1.3 min | 0.5 min |

| Water Content (%) | 57 – 67 | 49 – 55 | 44 – 50 | 58 – 68 |

| Particle Size Distribution on 1180 μm (%) through 300 μm (%) | 5 max. 1 max. | on 300μm 5 % min | ||

| Effective Size (mm) | 0.40 min. | 0.25 min | ||

| Uniformity Coefficient | 1.6 max. | |||

| Operating Temperature (℃) | 60 (OH-form) max. 80 (Cl-form) max. | |||

| Crosslinkage (%) | Ca. 4 | Ca. 6 | Ca. 8 | – |

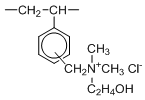

Type II has better efficiency to be regenerated though it has lower basicity and chemical stability than Type I. PA418 is generally used in water treatment.

PA408 is used to demineralize and to decolorize sugar liquors.

| Grade Name | DIAIONTM PA408 | DIAIONTM PA412 | DIAIONTM PA418 |

|---|---|---|---|

| Type | Type Ⅱ | ||

| Chemical Structure |  | ||

| Ionic Form As Shipped | Cl-form | ||

| Whole Bead Count | 95 min. | ||

| Shipping Density (g/L: approx.) | 720 | 685 | 685 |

| Salt Spliting Capacity (meq/mL-R) | 0.9 min | 1.1 min | 1.3 min |

| Water Content (%) | 54 – 64 | 46 – 52 | 38 – 44 |

| Particle Size Distribution on 1180 μm (%) through 300 μm (%) | 5 max. 1 max. | ||

| Effective Size (mm) | 0.40 min. | ||

| Uniformity Coefficient | 1.6 max. | ||

| Operating Temperature (℃) | 40 (OH-form) max. 60 (Cl-form) max. | ||

| Crosslinkage (%) | Ca. 4 | Ca. 6 | Ca. 9 |

Ion exchange resins with good uniformity in particle size increase their necessity to reduce the reagents costs and spent wastewaters in manufacturing pure waters. They are also used in other fields because they have a little amount of large particles easy to be broken by swelling and shrinkage. Gel type ion-exchange resins of uniform particle size are now launched to meet such necessity.

| Grade Name | DIAIONTM UBA100 | DIAIONTM UBA120 | DIAIONTM UBA200 |

|---|---|---|---|

| Type | Type Ⅰ | Type Ⅱ | |

| Chemical Structure |  |  | |

| Ionic Form As Shipped | Cl-form | ||

| Whole Bead Count | 90 min. | 95 min. | 90 min. |

| Shipping Density (g/L: approx.) | 680 | 675 | 715 |

| Salt Spliting Capacity (meq/mL-R) | 1.35 min | 1.3 min | |

| Water Content (%) | 43 – 49 | 49 – 55 | 45 – 51 |

| Average Diameter (μm) | 550 ± 50 | 575 ± 50 | 575 ± 50 |

| Uniformity Coefficient | 1.1 max. | ||

| Operating Temperature (℃) | 60 max. (OH-form) 80 max. (Cl-form) | 40 max. (OH-form) 60 max. (Cl-form) | |