212-204-0075

info@pyvot.tech

The Sunshell Advantage vs. Other Coreshell C18’s and Other Totally Porous C18’s with 2μm and Less Than 2μm

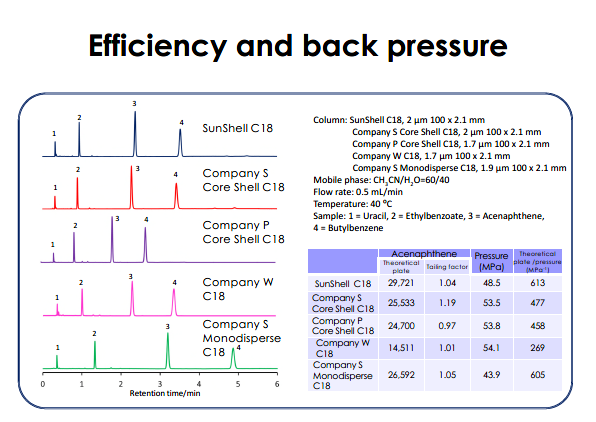

| Efficiency and Back Pressure | ||||

| Efficiency, theoretical plate number and a back pressure were compared between key columns.. Acetonitrile and water 60 to 40 was used as a mobile phase. Flow rate was 0.5 mL/min. This flow rate is typical for UHPLC. The theoretical plate of acenaphthene was measured. All C18 columns except for Company W C18 showed more than 24,000 plates. Company W showed a very low theoretical plate number. It is only 14,500 plates. The back pressure was around 50 MPa. Sunshell C18 48.5 MPa 7,034 psi 485 Bar Company S 53.5 MPa 7,760 psi 535 Bar Company P 53.8 MPa 7,803 psi 538 Bar Company W 54.1 MPa 7,847 psi 541 Bar Company S 43.9 MPa 6367 psi 439 Bar Monodisperse |  | |||

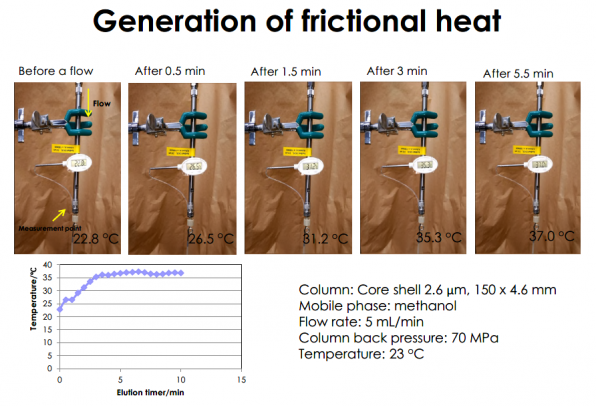

| Generation of Frictional Heat | ||||

| We measured the temperature of the surface of the column outlet when methanol flowed at 5 ml/min at 70 MPa. Initially temperature is 22.8 degree C, after 6 minutes, temperature then increased to 37 degree C. This means that frictional heat was generated in the column. Frictional heat is not a problem at below 25 MPa pressure. So when a 5um or 3um column is used, nobody notices an issue with frictional heat. |  | |||

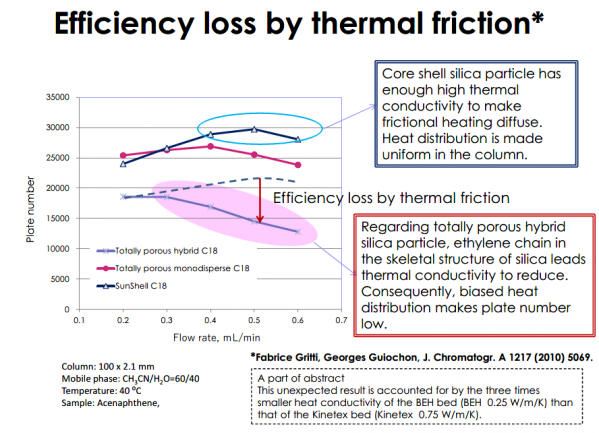

| Efficiency Loss by Thermal Friction* | ||||

| Regarding hybrid silica C18 columns, it shows a large efficiency loss from thermal friction. A 100 mm length column shows more than 50 MPa, so that the effect of frictional heat is larger compared to that with a 50 mm length column. Some scientists wrote papers regarding efficiency loss by thermal friction. Totally porous hybrid silica showed the highest plate number at a low flow rate of 0.2 ml/min because of efficiency loss by thermal friction at a high flow rate. Totally porous silica particle catches influence of thermal friction less than totally porous hybrid silica particle. |  | |||

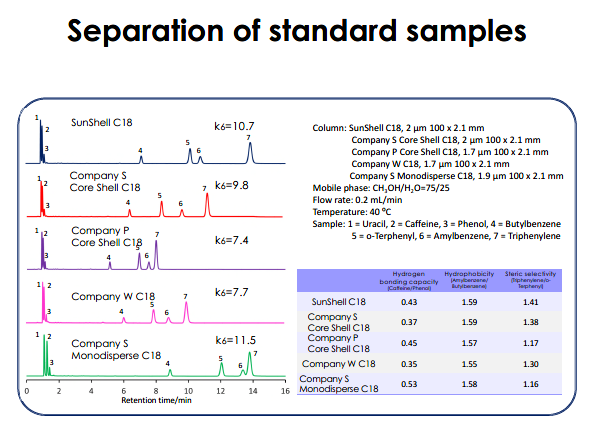

| Separation of Standard Samples | ||||

| This slide shows a comparison of separation of standard samples for 2 um or sub 2 um C18 columns as well as 2.6 um or 2.7 um core shell C18 columns. Regarding Separation Factor k6, company P and company W showed only 70% of retention factor of amylbenzene compared with SunShell C18. Company S shows almost the same retention factor as SunShell C18 although in regards to retention time, company S showed longer retention time than SunShell C18. |  | |||

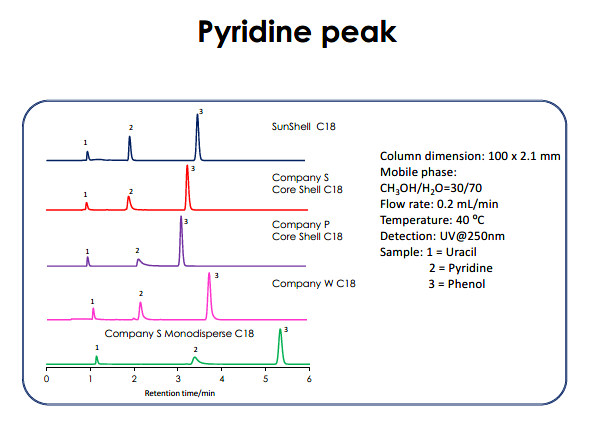

| Pyridine Peak | ||||

| Pyridine peak shape was compared and the effect of residual silanol groups was evaluated. Mobile phase is methanol and water 30 to70. Number 2 peak is pyridine. SunShell C18 showed the best peak compared to the other C18's. |  | |||

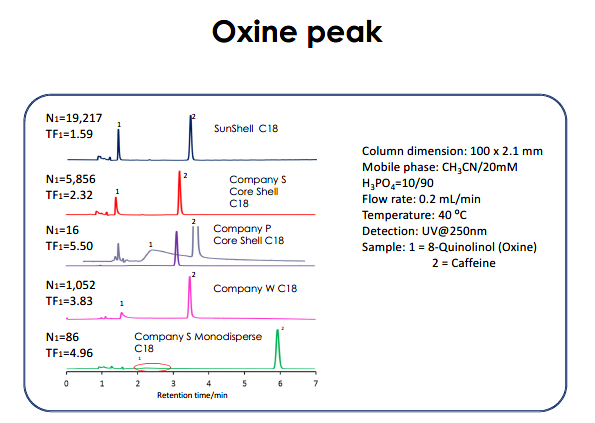

| Oxine Peak | ||||

| Oxine is a metal chelating compound. It is considered that Company P and Company S shows a low theoretical plate number and tailing. This means that they have a lot of metal impurities. Company W has a bad peak shape. SunShell C18 shows a good peak shape which shows that SunShell C18 has little metal impurities. |  | |||

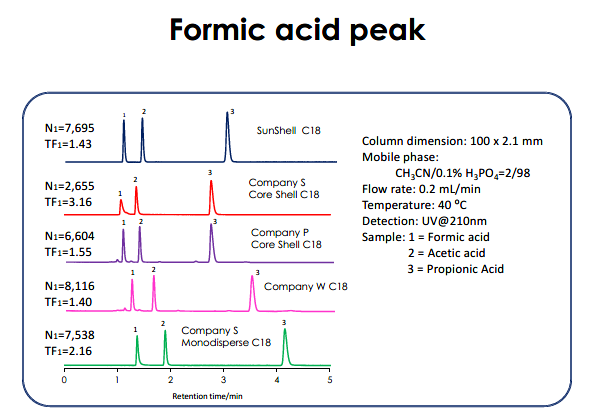

| Formic Acid Peak | ||||

| Sunshell C18 shows a good peak shape. |  | |||

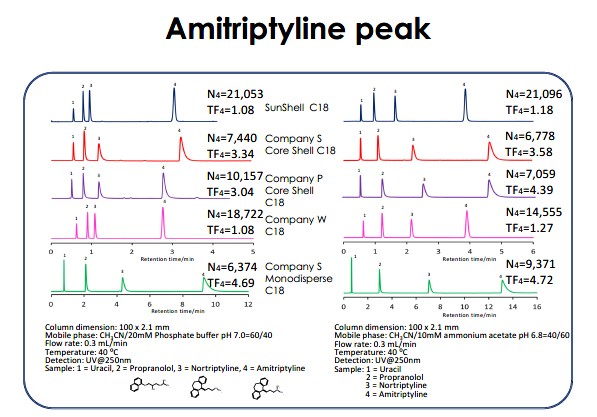

| Amitriptyline Peak | ||||

| Amitriptyline was used as a basic compound and two kinds of mobile phases were used. SunShell C18 showed the best peak shape and the highest theoretical plate for a basic compound like amitriptyline. |  | |||